Why 3D Printing?

Design, Rapid Prototyping, and Metal Replacement

Bonpez Additive 3D printing uses additive manufacturing of 3D printing in composite and metal materials for batch producing strong and durable objects and components.

Our three-dimensional printing machinery allows rapid 3D prototyping and production of articles with a notable saving of resources, not having to resort to industrial processing, and with a high level of customization.

3D Printing for Creating Components and Finished Parts in Various Sectors

3D Printing can be used in different industries and sectors, from Home and Shop Design to Automotive.

Industrial automation

In the field of industrial automation, 3D printing helps you create objects and components such as automated valve positioners or different types of collaborative robots and their components.

Industrial robots are often made to meet specific needs. 3D printing helps accelerate the process to make both customised parts and test prototypes.

Automotive

3D printing is now a common resource among major car manufacturers. High-performance tooling and spare parts can be achieved at low production costs, from conceptual models and prototypes to tools necessary to manufacture components, and even to the creation of actual components.

3D printing is also widely used to create discontinued components, among other applications.

Home & shop design

Experience the benefits of 3D printing in creating furniture and decorative components for homes and stores.

Through additive manufacturing, creating custom-designed handles, lighting supports, and many other design objects is much simpler, without the need to resort to production on an industrial scale.

Tooling

By applying 3D printing, you can create extremely resistant tools using materials such as stainless steel and onyx that are needed for manufacturing processes across various fields- from components for complex machinery to moulds for industrial presses and metal milling heads.

3D printing also makes it possible to manufacture tools or their components at low costs.

Four 3D printing technologies available

Polymer 3D printing

Our 3D printing technology for composite materials creates highly resistant objects by using a base material (PA6 reinforced with chopped carbon particles) that can be further strengthened with various types of continuous fibres, such as carbon, glass, and Kevlar.

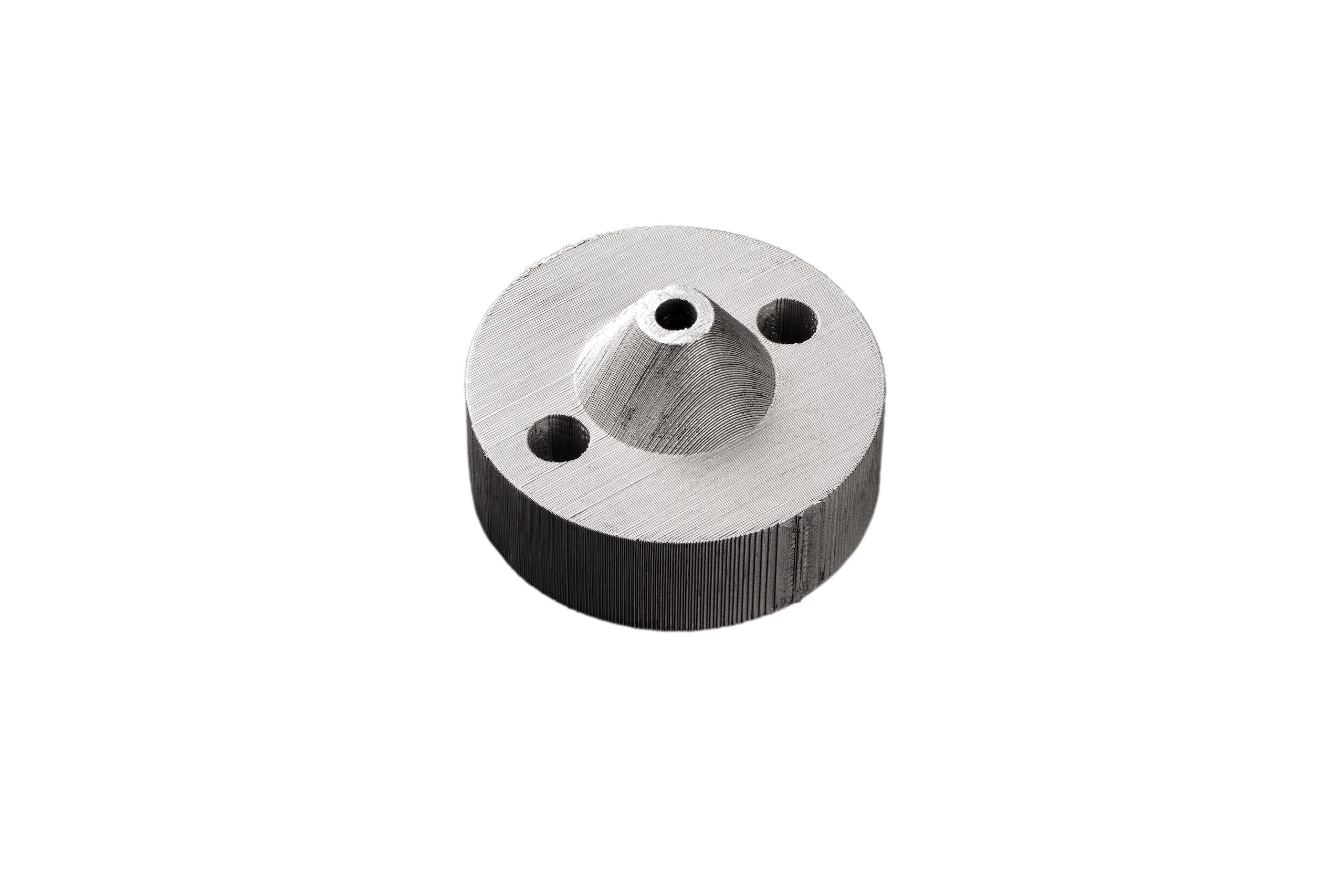

Metal 3D Printing

3D Printing using metal alloys results in direct, easy, and extremely fast production of complex components.

Through 3D printing, you can go directly from design to final functional metal components while reducing not only manufacturing times but also costs

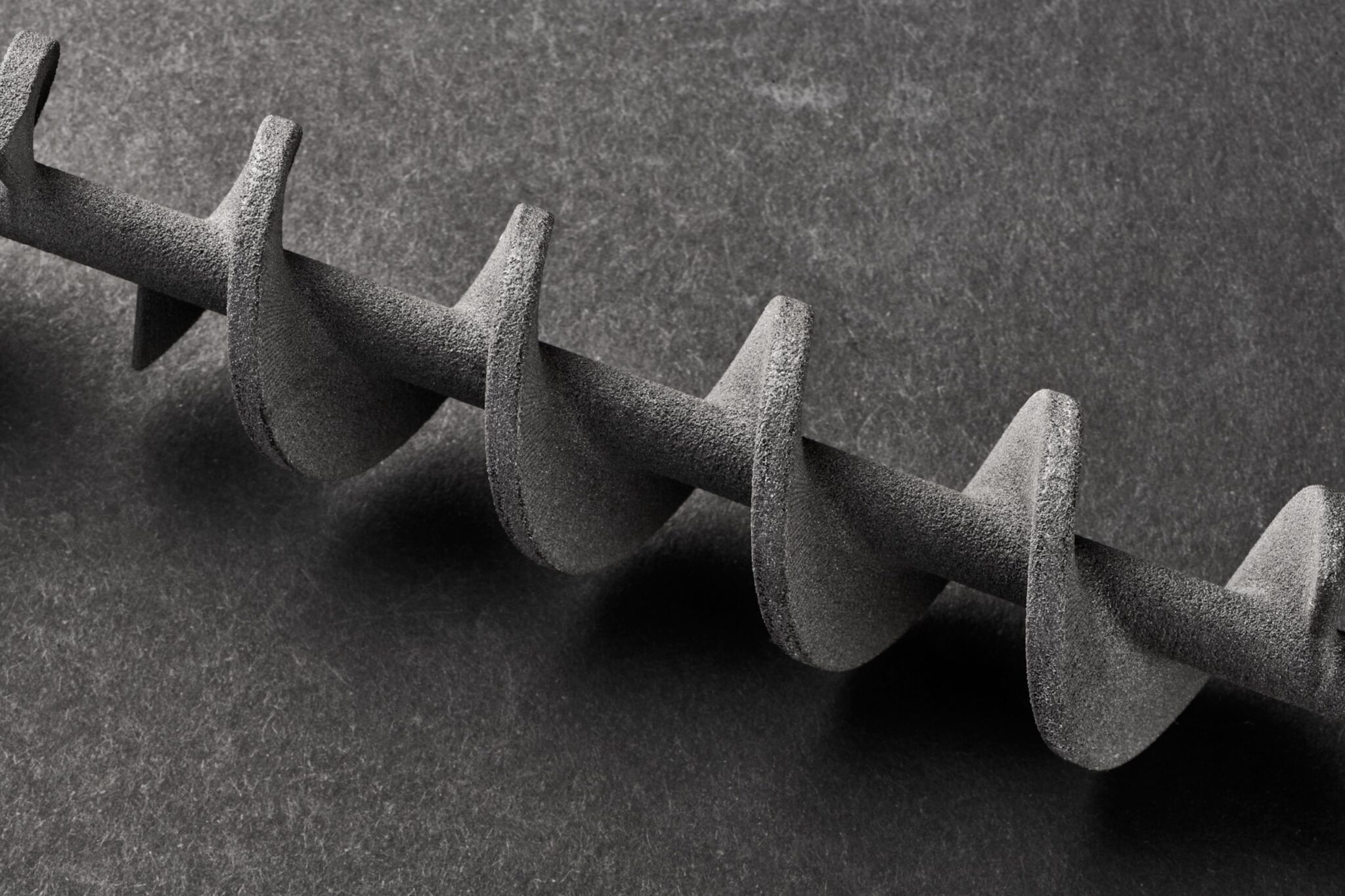

Nylon 3D Printing

Thanks to the Nylon 3D printing, with Selective Laser Sintering (SLS) technology, components with complex geometries and hollow internal structures can be made using bio-compatible thermoplastics, such as Nylon PA12, which can be sterilised in autoclaves and exhibit high isotropy across all spatial planes.

Photopolymer 3D Printing

With 3D printing technologies for photopolymers like Digital Light Processing (DLP) and Stereolithography (SLA), components with unparalleled aesthetic finish in the additive manufacturing world can be achieved, thus ensuring high-resolution details thanks to certified materials: flame retardant, ESD, bio-compatible, and resistant up to 300°C.