Onix

Nylon filled with carbon microfilaments that creates precise parts with a perfect finish as a result of its versatility. Using Onyx ensures strength, toughness, and chemical resistance.

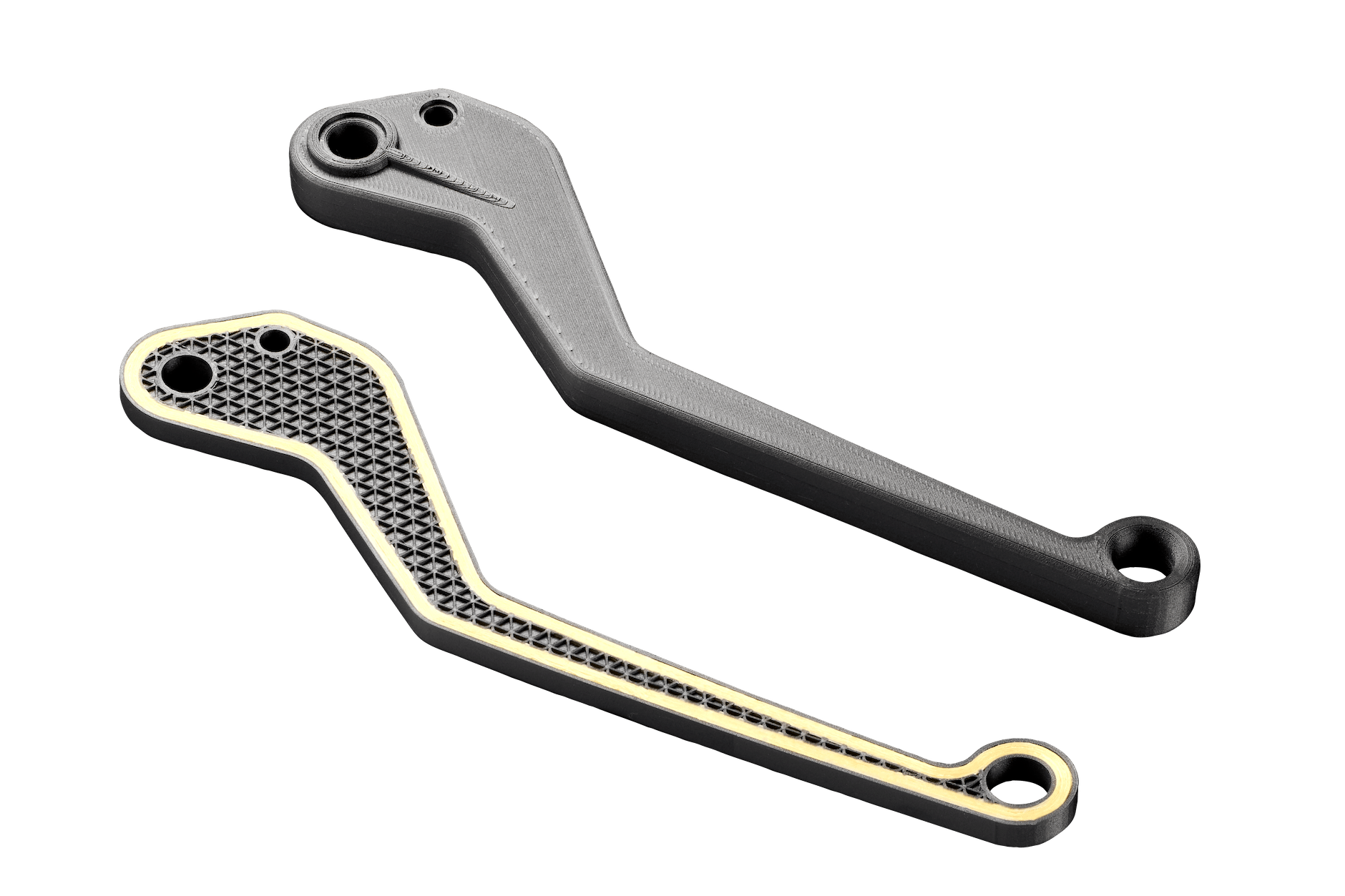

3D printing using polymers, such as carbon fibre, creates components and final objects with high strength and tensile properties, and enables replacing metal in various fields of application (metal replacement).

Polymer 3D printing uses a base compound that is reinforced with various types of continuous fibres, such as carbon fibre, to enhance its breaking stress, shock resistance, and yielding.

Bonpez uses Onyx as the base material. This is a polymer that ensures high dimensional stability, requires no post-processing work, and does not produce hazardous powders. Moreover, Onyx processing is energy-efficient, making it more cost-efficient and sustainable.

The CFR (Continuous Fiber Reinforcement) 3D printing technology helps create components as strong as aluminium directly on the workbench.

CFR 3D printing offers the chance to create rigid, durable components that can replace solid machined aluminium.

This technology incorporates reinforcement with various types of continuous fibres into a base composite:

Composite 3D printing always begins with a base material, which can be:

Nylon filled with carbon microfilaments that creates precise parts with a perfect finish as a result of its versatility. Using Onyx ensures strength, toughness, and chemical resistance.

Easy-to-print plastic available in various colours, economical, and suitable for prototyping.

High-sliding thermoplastic ideal for producing ergonomic surfaces and supports for delicate parts.

In composite 3D printing, various continuous fibre reinforcement components can be added to the base composite:

Extremely rigid and strong material that, when combined with a base composite, can produce components with strength comparable to 6061-T6 aluminium. There is also a fire-resistant variant, Carbon Fibre FR, that offers an even higher strength.

Highly resistant material used mainly in high-impact applications; can produce components that are extremely resistant to impacts and nearly immune to breaking.

Heat-resistant continuous fibre suitable for industrial applications.

Differs from regular glass fibre as it shows higher mechanical strength (almost equivalent to 6061-T6 aluminium) and high-temperature resistance (up to 145°C).

Polymer and composite 3D printing is highly versatile and easily adapts to various uses, including: