3D Printing and Additive Manufacturing

3D printing is a manufacturing process that uses specific printers to create three-dimensional objects from digital models.

3D printing is also known as ‘additive manufacturing’ because, unlike traditional subtractive manufacturing, it uses the addition of material as the creation process.

Bonpez’s 3D Technology

Photopolymer 3D Printing

DLP Printing Technology

DLP (Digital Light Processing) 3D printing is a technology used to quickly manufacturing parts using photopolymers, which are polymers or resins that can absorb a portion of light and become solid and compact.

Due to its precision, speed, and cost-effectiveness, this 3D printing technology is often used to print resin objects with complex designs, such as toys, jewellery moulds, dental moulds, and other items with refined details

SLA Printing Technology

Similar to DLP, SLA (Stereolithography) technology transforms photopolymers into hard plastic using a light source (either a laser beam or a projector). This results in high-resolution, precise, and versatile objects with highly accurate details.

Unlike DLP printing, surface finishes applying SLA are smoother as resin is polymerised point by point on the print bed.

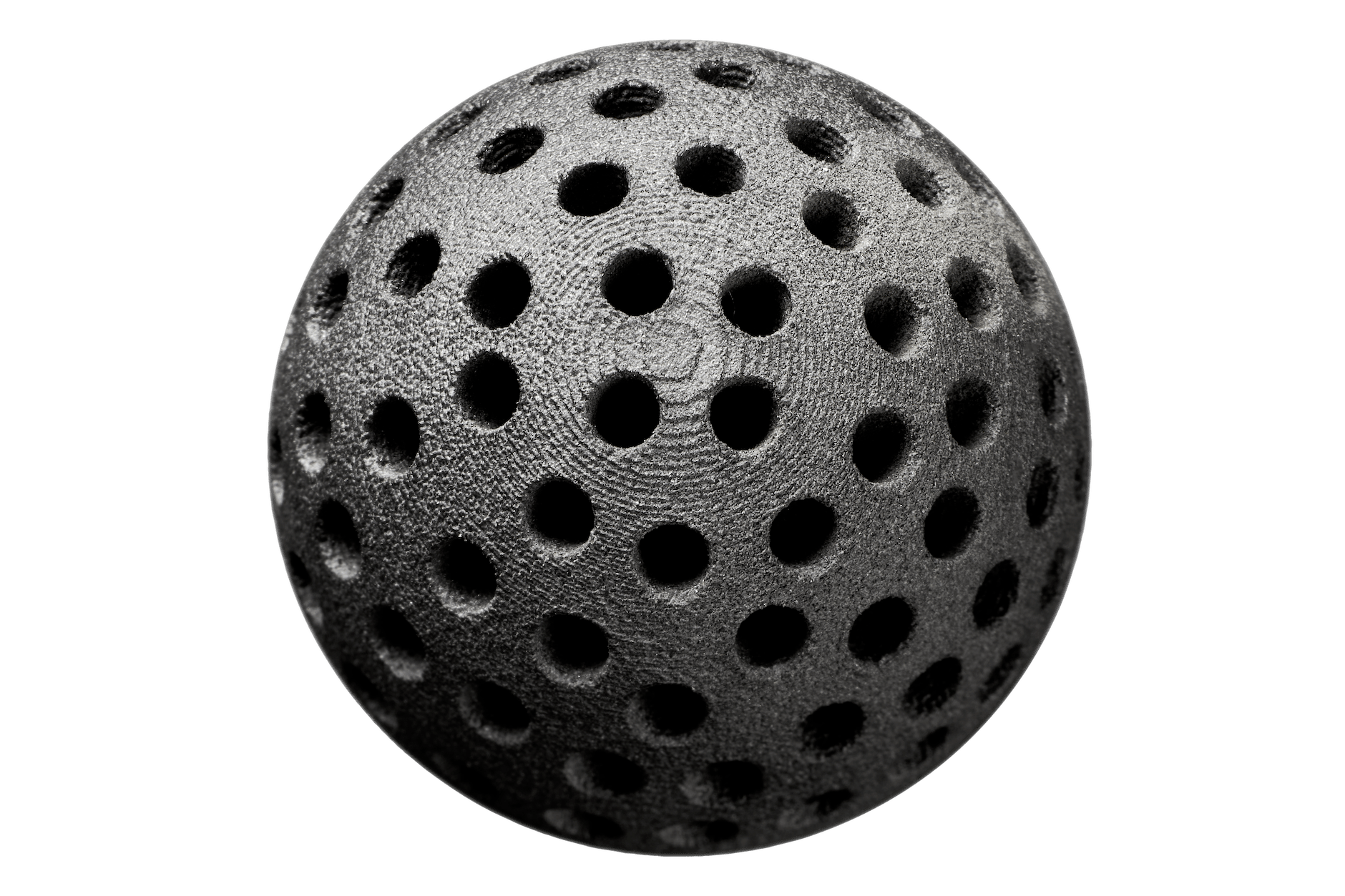

Nylon 3D Printing

The SLS (Selective Laser Sintering) 3D printing technology uses a laser to fuse nylon powder, and achieves components parts with complex designs- such as protruding elements and intricate or interlocking geometries- at extremely high productivity

Today, we can print Nylon 12, one of the most widely used and requested thermoplastics on the market, known for its high design freedom.

We are getting ready to meet even more ambitious requests, such as glass- or aluminium-filled nylon powders.

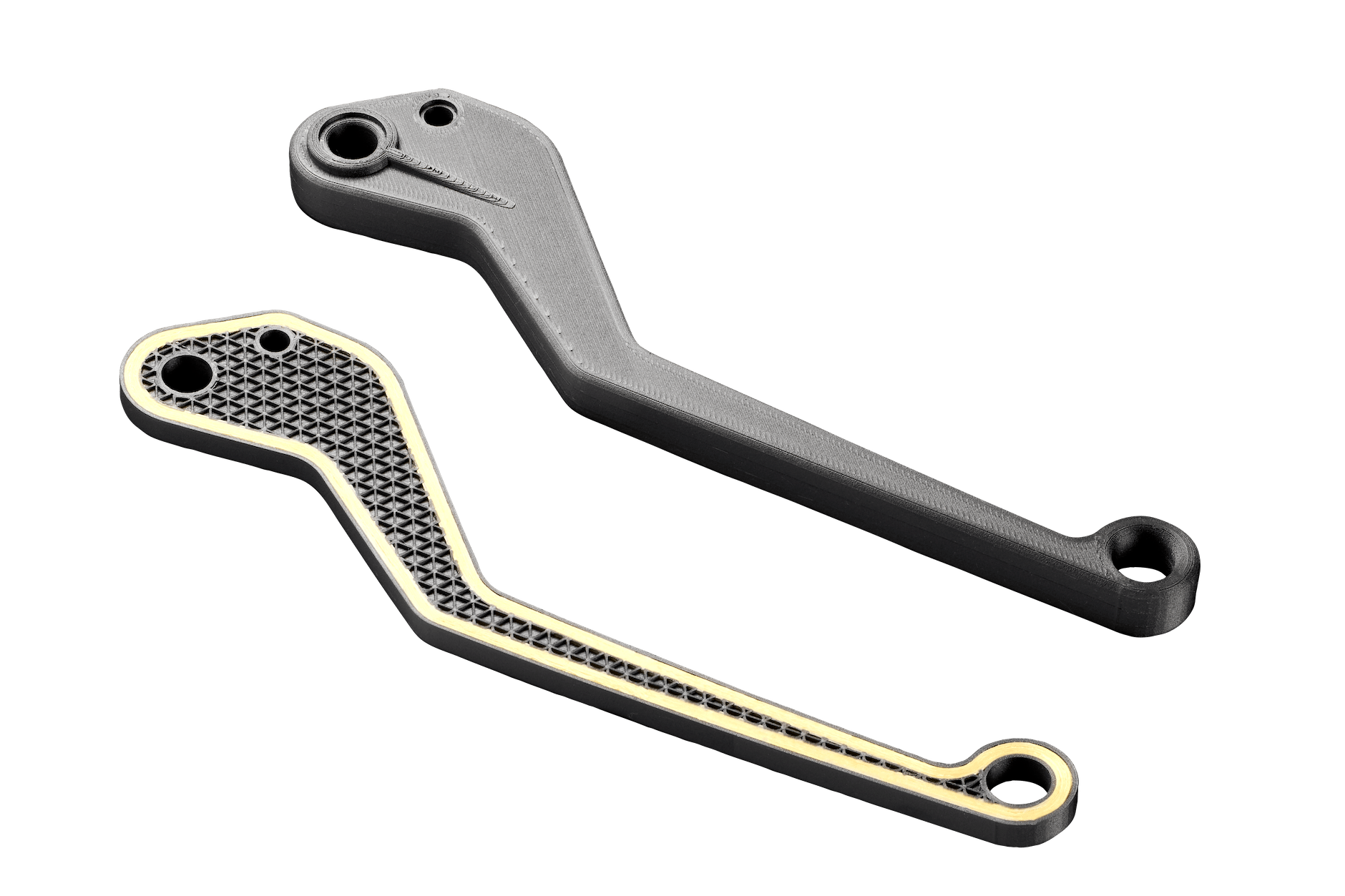

Polimer 3d Printing

The CFR (Continuous Fiber Reinforcement) 3D printing technology is used to create components made of composite materials reinforced with continuous glass filament, Kevlar, and carbon.

This enables us to introduce metal replacement, that is, replacing metals with polymers for lighter finished products featuring more complex geometries and a low environmental impact.

By applying CFR technology, mechanical characteristics equal or superior to aluminium with significantly reduced masses can be achieved.

Metal 3D Printing

We use the innovative ADAM (Atomic Diffusion Additive Manufacturing) 3D printing technology for metal alloys.

ADAM is a cutting-edge additive manufacturing technique that enables making parts using various metal alloys without constraints on material change. We can print different metal materials with the same machine, such as stainless steels, tool steels, pure copper, and Inconel 625.

What Can Be Printed?

Discover some of the latest objects created by Bonpez: