Nylon 12

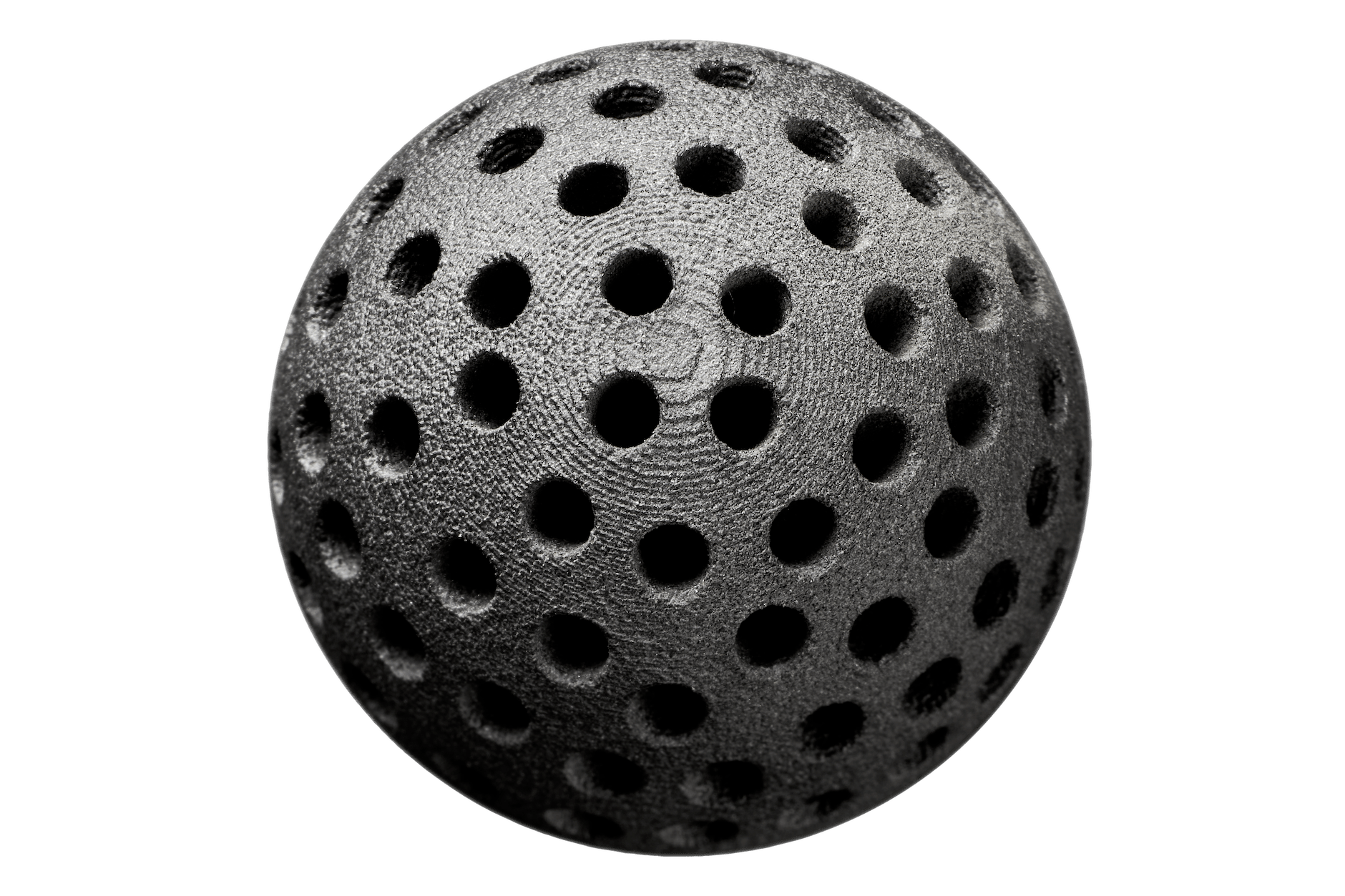

An extremely versatile material, suitable for making functional prototypes as well as components for final use or parts with complex geometries.

In additive manufacturing, nylon powders melt to form the desired object, layer by layer, giving the product a unique quality.

Nylon powders are among the most widely used materials in 3D printing. They are chosen due to their versatility, strength, elasticity, low cost, and ease of production. These characteristics are also associated with high-precision products, achieved through SLS technology that utilises plastic powders instead of traditional filaments.

SLS (Selective Laser Sintering) 3D Printing is a particular additive manufacturing (AM) technology that, by using a high-powered laser, synthesises particles of nylon powder following a 3D model and transforms them into solid objects. SLS 3D printing is highly favoured among engineers and manufacturers because, in addition to create products with excellent mechanical characteristics (nylon components made through laser sintering achieve nearly 100% density), it offers high design freedom. This makes it suitable for rapid prototyping and manufacturing small batches or custom production: it is easy to print complex designs with features such as protrusions and intricate or interlocking geometries.

These are the nylon and thermoplastic powders currently available:

An extremely versatile material, suitable for making functional prototypes as well as components for final use or parts with complex geometries.

3D printing with nylon powders, applying SLS technology, is ideal for:

3D printing using nylon or thermoplastic powders is chosen because it makes it easy to print complex designs with protruding elements, intricate geometries, snap-fit parts, internal channels, and more.

It ensures: